Hazards involved in solar plant operations

|

Hazards involved in solar plant operations The Solar Rooftop Installation in India is growing tremendously every year. With this growth of solar sector, number of personnel working on Indian roof has also increased. Along with this growth in workforce, the risk associated has increased. The hazards mainly involve fall or trips from heights, electrical, weather related hazards and other common hazards.

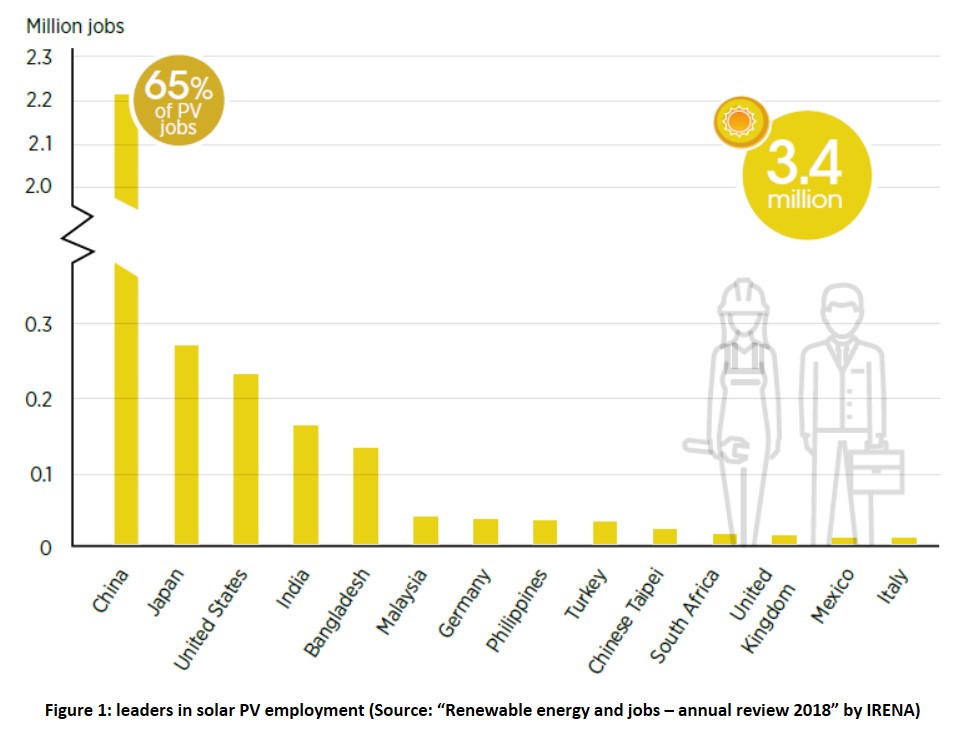

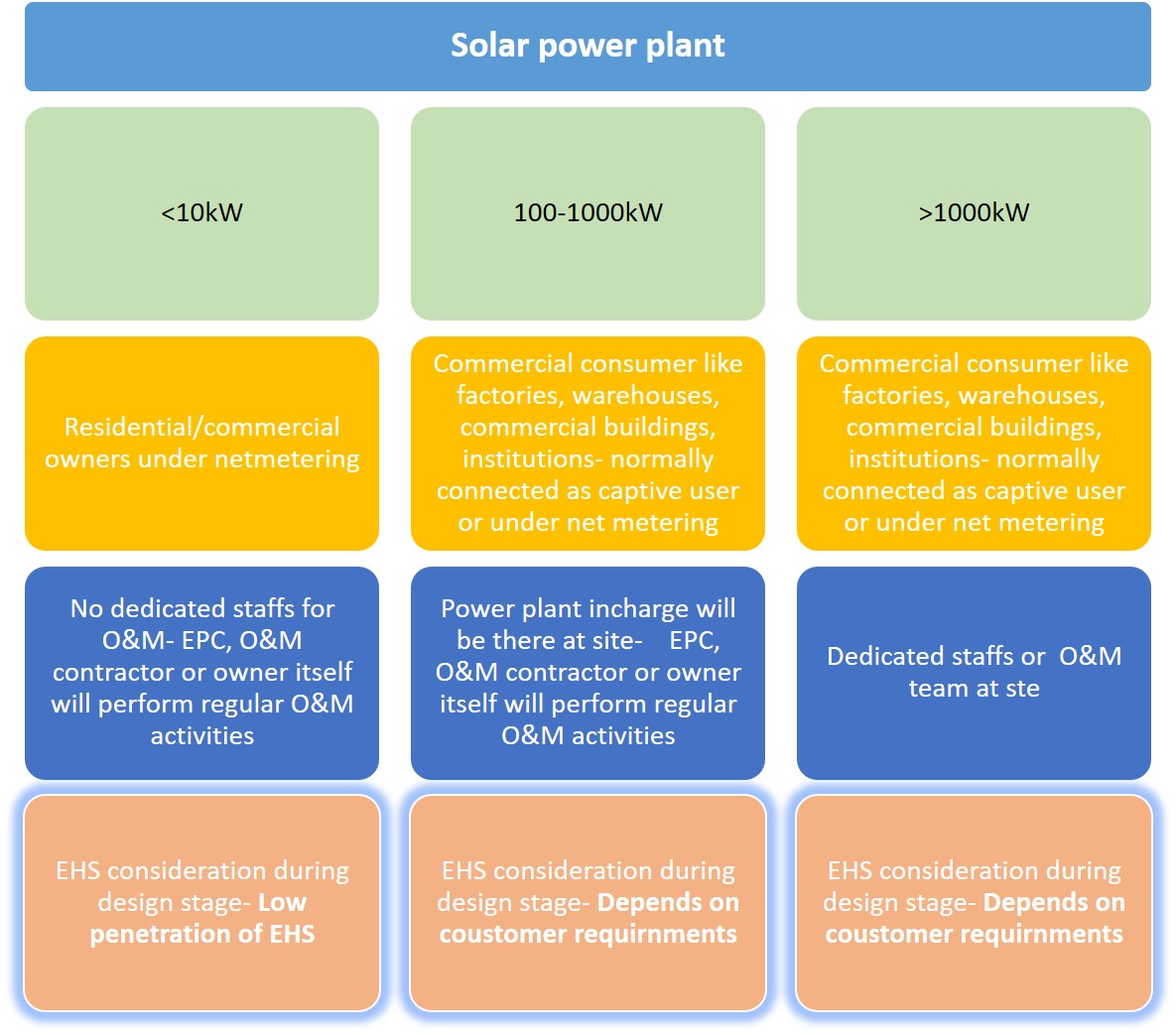

As per recent report published by IRENA India’s renewable energy job sector is growing rapidly especially in shoulder of solar industry. Since the projected target of installation is 40GW rooftop capacity by 2022; the above employment number is expected to increase exponentially. Parallel to this O&M market is also growing rapidly. In case of utility scale projects dedicated O&M teams are involved in operational activates of solar power plants, were it is lacking in rooftop solar. According to current market scenario rooftop projects can be divided as follows:

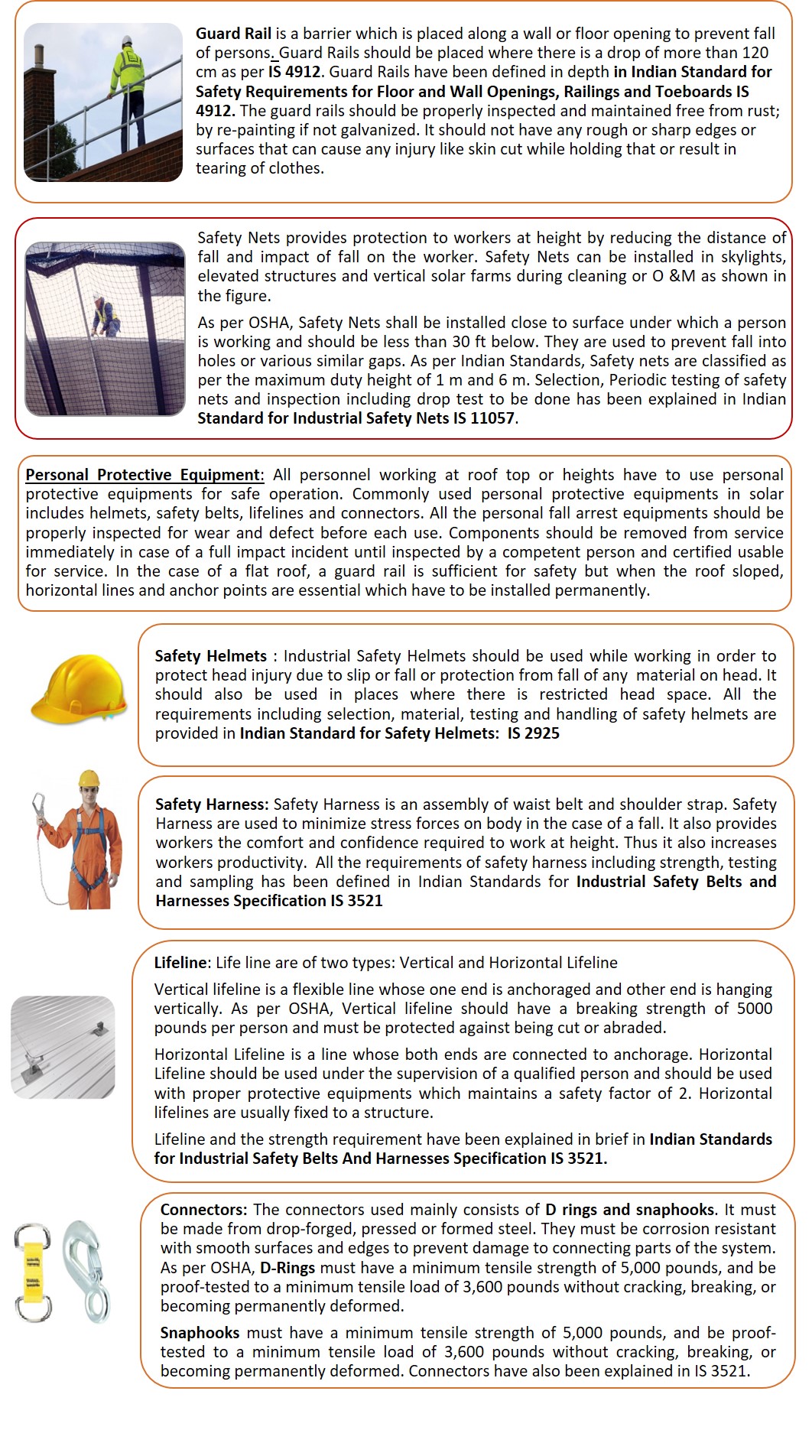

1. Fall from Heights The solar rooftop power plants are installed at high rise buildings, elevated structures and sloping roofs. The workers who are performing routine operation and maintenance activities including cleaning of PV modules are prone to hazards of falls. Also the weather can host of problems, like the slippery, wet, or icy roofs, snow accumulation, dangerously hot temperatures, and heavy wings. Any of these condition can definitely increase the chance of a fall, and even more so when they’re present in combination. Falling from height can lead to serious injuries including deaths. The walking areas on the roof are reduced with the increasing capacity of solar panels. It is better to be prepared for any weather condition by making your roofs safe and able to withstand the climate in which it exists. Make sure there are clear, safe paths foe workers to use when accessing the roof, and eliminate non-essential roof access during hazardous conditions. A thunderstorm isn’t the time to be performing routine maintenance. As per OSHA (_______________________), workers who are working at a height above 6 feet or more should be protected by following methods a) Guardrails : b) Safety net systems c) Personal fall arrest systems

Slips at roof is a potential hazard which has to be considered. slips occurs as person loses balance and falls due to lesser fiction between roof surface and footwear. In India, Major slippage at roof occurs due to the following reasons

3. Trips at roofs Trips occurs as person losses balance and falls when foot collides with some obstruction. Common causes include obstructed view, irregular walking surface, poor lighting, uncovered cables etc. This can be prevented by:

4. Electric shock

Electric shock is sudden passage of electric current through the body. This can lead to burns or even death in severe cases. Electric shock can lead to involuntary reaction of body reaction which can lead to fall or slip, burns, respiratory block or even death. Effect of electric shock also depends on various physical characteristics such as body weight, moisture content and skin sensitivity. So threshold limits for electricity varies among individuals but mostly women and children tend to have lower threshold limits as compared to adult men. As per NFPA 70E® Standard for Electrical Safety in the Workplace assumes that less than 50V is considered safe from standpoint of electric safety hazard. But for wet surface, if DC voltage exceeds 30V then it is considered to be a shock hazard. When the voltage exceeds 50V AC or DC and is in shock hazard zones, the operator has to wear rubber insulating gloves and leather protectors. Cause: This can happen even with contact with wires of a broken energized panels or poor earthing. Electric Shock Protection Electric shock protection is obtained by making hazardous live parts inaccessible to direct contact. For protection following steps to be taken :

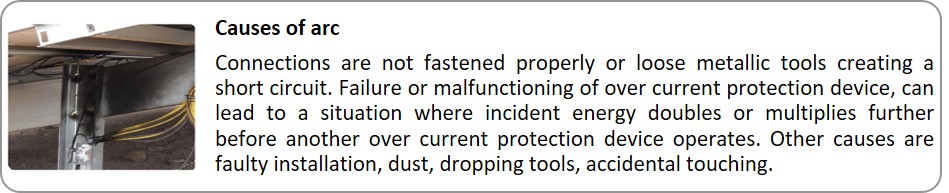

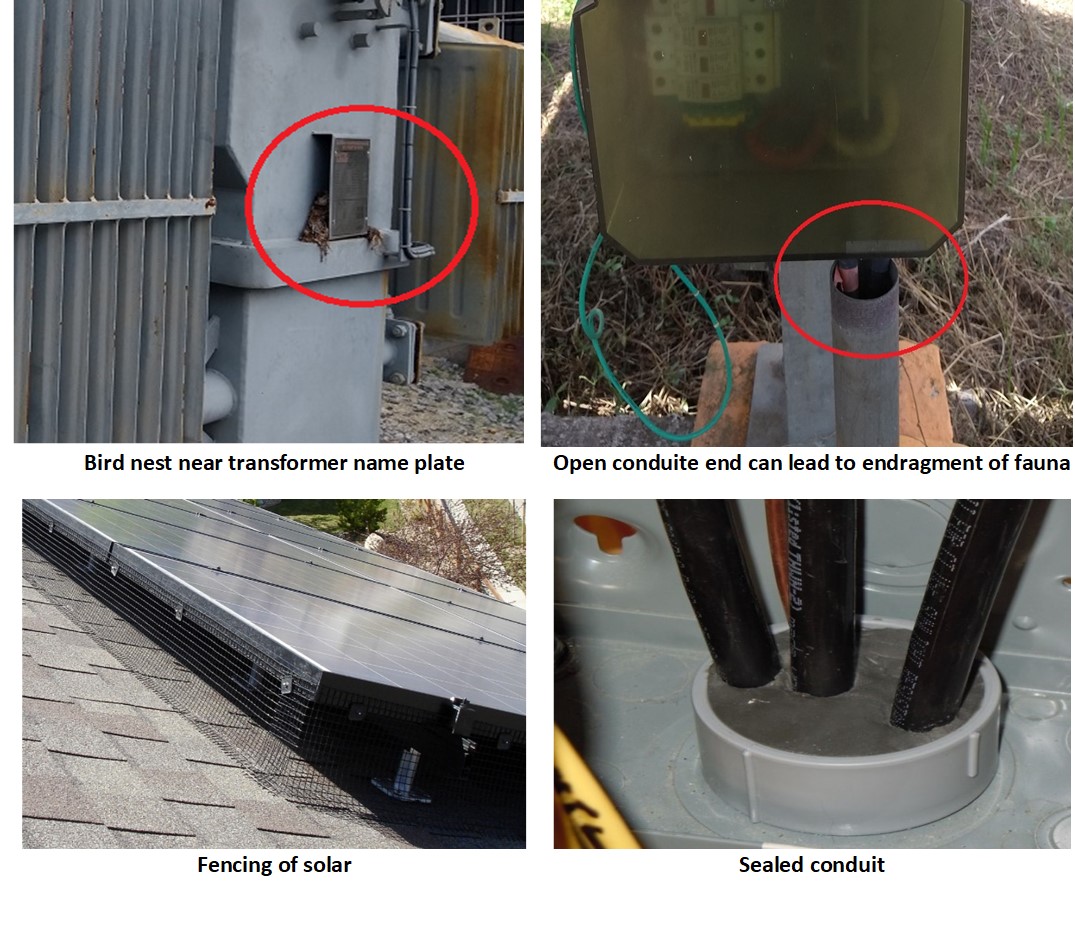

5. Electric Arc An arc Flash occurs when the short circuit has been opened but circuit breaker has failed to trip or fuse failed to blow. This occurs between corroded or loose connections. This arc fault results in an arc flash or a spark occurring between connections which may lead to fires or even eye damage due to ultraviolet rays. An arc flash might be accompanied by arc blast in which energy is released explosively by intense sound pressure and vapourized metal. The incident might lead to worker to fall or slip which can cause severe injury. The risk of serious arc flash is negligible from a single module. But when connected together in the form of strings and tables, output current increases. This can pose serious injury or even death if human is present in close proximity. When the arc flash occurs the temperature can reach up to 90000 C which can cause serious burn. Electric arc is not voltage sensitive but is a more a product of short-circuit current and clearing time or arc duration. Generation of higher arc energy from a low voltage source than high voltage source is possible in some cases. Typical results from an arc flash are burns, fire, flying objects (often molten metal), sound Blast (noise can reach 140 db – loud as a gun), extreme Heat 6. Fire PV module fire is caused mainly by insulation failure or internal shorting. During a fire at day time, since the PV system is energized, this creates internal arcing and shock. The supporting mounting structure or surrounding surface may get energized and can create further electrical shock or arc flash risks. This increases the fire fighters risk while working in rooftops and other elevated structure. Utility PV systems are usually in open areas and, although their output is greater, present fewer obstacles and are easier to isolate than residential systems. In the case of fire, fire fighters are subjected to electrocution risk. PV module continues to generate voltage in the case of fire even if the system is shut from AC Side. Building roof is under stress due to PV Panel installation. If the Roof is not having sufficient strength or a fire occurs in building due to which strength decreases, there is a possibility of collapse. During fire, hazardous fumes may be released which can pose danger to human health. 7. Structure Solar panels can detach and fall from roof due to loose connections to structure or breakage of module mounting structure (MMS). Poor design, manufacturing and installation issues, corrosion of structure can also create hazards. Any structure with sharp edges which pose a danger to create cut should be smoothened.Failure of rusted structure or fasteners can lead to fall of panels. Rusted galvanized structure should be replaced during period of warranty or rusted part of structure should be coated with zinc spray. 8. Flora and Fauna Animal and birds may be present in the surrounding agricultural lands or surrounding area which will enter into installed solar plant and can cause damage the panels or wires, this will make hazardes situation like earth fault, short circuit, DC arc or electrocution. Following damages can be arises by different flora and fauna

Also doors and windows of unoccupied buildings inside the plants should be properly closed to avoid nesting of bees or birds. When equipment, vehicles, offices with open doors, are left unattended or open for extended periods it has the potential to become habitat for native species. Taking insurance for the same can also reduce the risk associated with this menace. 9. Thermal burns and sun burn When the sun is heating the solar panels, the surface of the panel become extremely hot and if touched with naked or direct exposure to sun during the high temperature time and can lead to burn or sun burn/ stroke. The glass and other metal components can reach temperature of over 900C during the peak production time and can lead to burn. Use of leather gloves can mitigate thermal burn risks. While working on field it is better to use sun protection cloths, skin creams, UV protection eye wears etc. 10. Wind

As per IEC 61215, solar panel can with stand wind load of 2,400 Pa equivalent to a wind pressure of 141.5km/hour. Above this limits panels can get damaged. There is risk of person getting injured by a falling panels or shattering of glass of solar panels which can cause cuts. When the panels are replaced after disconnection and locked out/ tagged out, there is risk associated if there is high wind. Therefore, when the wind speed is equal to or greater than 15 mph PV module replacement should not take place. Keeping a track of the weather and inspecting the tightness of connections may reduce the probability of PV modules flying off. Also the plant has to be properly inspected for any possible hazards and breakage after a major storm. 11. Hail Hails are irregular shaped balls formed by super cooled water whose formation takes place in clouds. Hails can tend to a size ranging between 5 and 150 mm diameter. AS per IEC 61215, solar panels should withstand hails stones of 25 mm in diameter which weighs 7.53 grams with a velocity of 23 meter per second. Good quality panels can withstand larger hails at a faster speed. Hail can result in cracking of glass protection of solar panels. This can damage panel and also expose live wiring which is a serious hazard. Solar panels can withstand hail size of golf ball but unusually large hail storms can damage the panels. 12. Lightening Lightening is a major hazard in solar plants. This can lead to damage of panels, fire or even loss of life. Lightening arrestors and surge protectors protect the solar panels and electronic components from damage which works along with grounding. Effective grounding is the key to lightening protection. Testing of lightening arrestors, earthing pits and grounding of the system should be a part of operation and maintenance schedule. Solar plants are also subjected to environmental risk such as floods, earthquake, landslides and storms. Continuous immersion in water has the potential to damage the junction box. The junction box should be of IP67 and cable should have resistance to water absorption.

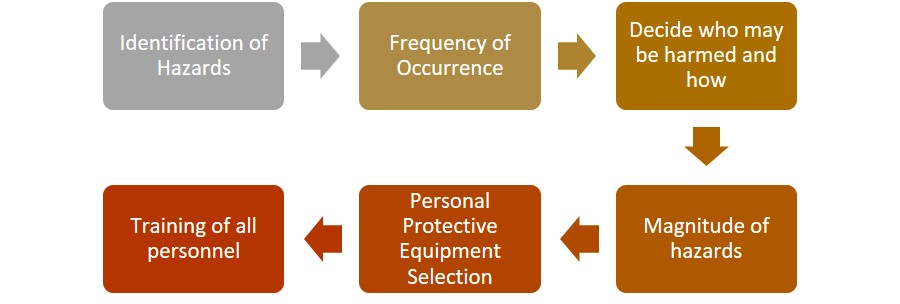

Landslides or soil erosion is also another major hazards if soil beneath the foundation is washed away as shown in the figure. This can also lead to loss of generation, dangerous situation leading to damage of panels and also risk in maintenance activities of the plant. By constructing proper storm water management system these issues can be avoided to an extent. And also can be avoided by planting and maintaining the grass and other vegetation at the site which increases water holding capacity of the plant. 13. Theft There is a possibility of theft of solar panels and cables especially in rural locations. To protect against thefts, additional security measures like anti-theft module fasteners, fences, video surveillance etc. are required.  In addition to this, do not keep any ladder or other items in open which can make it easier for thieves to access the solar roof. Also do not boast about the cost of solar panels around to prevent any un avoided attention. The Assessment of Need for PPE of a site (Source: OSHA PPE) It is the responsibility of every employer to provide possible protection to all workers in the workplace. The cooperative environment between employee and worker helps in maintaining a safe working and healthy environment. Employer has to assess the workplace for all the potential hazards involved which necessitate the need for PPE. For developing a comprehensive safety and health program first all the physical and health hazards involved should be identified in the workplace. This is hazard assessment. A solar power plant is subjected to different hazards like fall from heights, sharp objects, electric connections, lightening, snake bites etc. So hazards Assessment of a site is of utmost importance which can ensure the safety of workers involved in the plant. In the assessment first the site has to be surveyed for developing the list of potential hazards which will vary from site to site. Hazard identification and risk analysis has been detailed in Indian Standard Code for IS 15656. Following steps have to be followed for site assessment

1. Identification of All Hazard First step is to identify possibility of hazards, type of various hazards and cause of hazards. Hazards in a solar power plant we have explained earlier. 2. Frequency of Occurrence Detailed investigation has to be carried out in finding the potential frequency of occurrence of various hazards at site. Proper analysis has to be made to find which type of hazard can be expected to occur at what season and frequency. For example, rate hazards caused by vegetation growth will be high during rainy season. Probability of occurrence can be classified into high, medium and low. 3. Decide who may be harmed and how After listing out the hazards and probability of occurrence, the numbers of personnel who can be harmed by the potential hazards have to be identified. For example, workers doing the cleaning activity of solar PV modules at heights are at risk of fall. Also the risk faced by new employees, contract workers, site visitors, clients etc. have also be considered. In case of utility scale power projects and >1MW rooftop power plants this step having high impotence. 4. Magnitude of hazards: In this step, the strength and magnitude of hazardous event should be calculated and scaled. The impact of some of the hazards can directly lead to fatality. In other situations, hazards can cause minor cuts, electric shock etc. Even after all precaution some risks always remain. So they can be classified as high, medium and low risk based upon the magnitude and strength. All identified hazard should be recorded and properly reviewed. Evaluation of each hazard should be done by considering the severity of each outcomes, the probability of occurrence and number of workers exposed to each hazard. All available method to eliminate the risk of each hazard should be implemented. In cases where hazards cannot be eliminated, proper PPE should be used to protect workers against hazards. Hazards should be prioritized so that highest risk are addressed first. Solar Site should be periodically reassessed for any changes in or operating procedures that could affect occupational hazards. 5. Personal Protective Equipment Selection After the proper hazard identification and analysis, all necessary PPE are selected as per the hazards. Thus, PPE is implemented as the last measure of protection when worker exposure to potential hazards cannot be totally eliminated. PPE should be made available at site before start of work. 6. Training (Source: PPE USE AND SELECTION GUIDE : ISEA) All the workers should be trained under experienced and competent trainer before using any site. Live hands on training is mandatory to help all users to understand all the features, capabilities and limitations of various PPE. After the completion of the training workers must be able to:

References [1] http://www.bridgetoindia.com/wp-content/uploads/2017/12/India-Solar-rooftop-Map-Dec.pdf [2] Year End Report MNRE : http://pib.nic.in/newsite/PrintRelease.aspx?relid=174832 [3[ OSHA- Occupational Safety and Health Administration [4] Safety Of People: Recommendations For DRRG Solar PV Systems ; DEWA [5] The Effects of Electrical Hazards Madhav N. Thaker , Bhagwant N. Phadke , Praveen D. Patel, Institute of Engineering & Science, IPS Academy, Indore (Madhya Pradesh) [6] Hazards in the installation and maintenance of solar panels: IEEE, James R. White, Mike Doherty [7] https://www.solarreviews.com/news/rodents-wreak-havoc-on-rooftop-solar/ Vertical Solar Farm https://economictimes.indiatimes.com/industry/energy/power/tata-power-solar-dell-india-build-vertical-solar-farm/articleshow/58684041.cms Slippage at roofs https://www.ccohs.ca/oshanswers/safety_haz/falls.htm |

About Project

Under USAID- PEER cycle 5, World Institute of Sustainable Energy has done research study to strategizing O&M and performance evaluation of solar PV power plants in India. Project team has visited more than 100 power plants all across India and done exhaustive study on national and international best practices, standards ... Ream More

Useful Links

Articles by Subject

Our Contact

Plot No.44, Hindustan Estates,

Kalyani Nagar, Pune 411 006, India

(020) 26613855

(020) 26613832